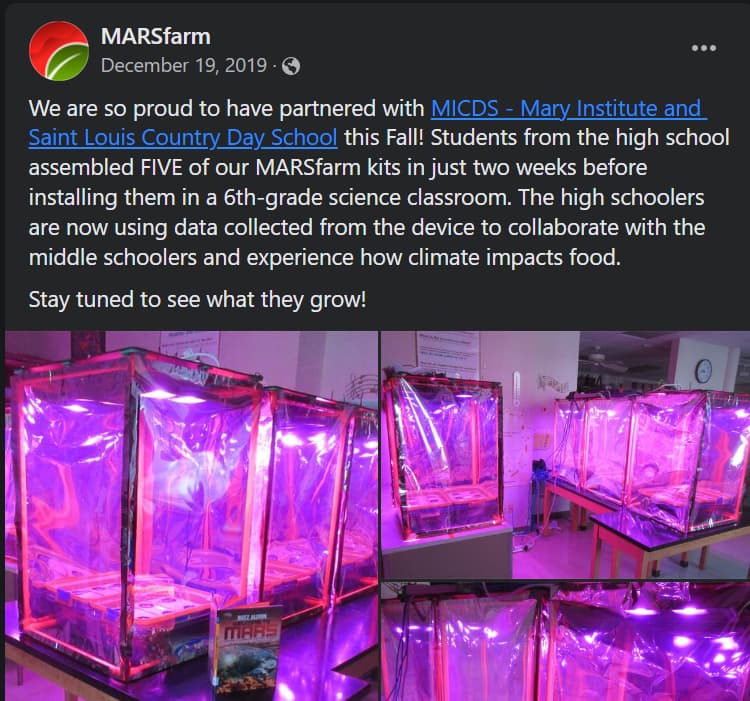

Before releasing the MARSfarm Mini in 2020, we sold several larger versions of the MARSfarm, known as “MARSfarm Large” ![]() . This helped us to learn how teachers wanted to use our equipment and through these early sales we were able to observe it actually being used by students in a classroom. We tested several sizes, lighting configurations, and manufacturing techniques throughout this time. This is when we made our transition from using mostly off-the-shelf parts and woodworking machinery to using 3D printers and CNC machines to manufacture custom plastic components - still in @drew’s garage though!

. This helped us to learn how teachers wanted to use our equipment and through these early sales we were able to observe it actually being used by students in a classroom. We tested several sizes, lighting configurations, and manufacturing techniques throughout this time. This is when we made our transition from using mostly off-the-shelf parts and woodworking machinery to using 3D printers and CNC machines to manufacture custom plastic components - still in @drew’s garage though!

MARSfarm Large V0.42 (2019)

This was the first product that we ever sold to a school. It was a private school (what a suprise) here in St. Louis named MICDS. The school had a wonderful high-school science teacher, who was formerly a plant scientist, that allowed me shadow their classes and observe students assembling/using them. As someone who was homeschooled K-12 this was extremely insightful.

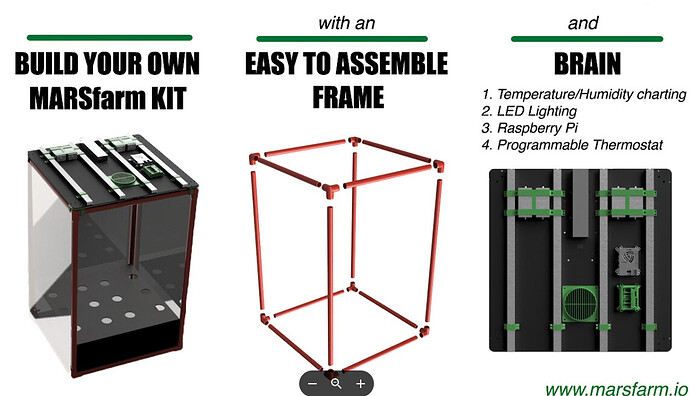

Open-Source “Food Computer” (2017)

My first project with my co-founder, Drew Thomas, before even starting MARSfarm was to design a “Minimum Viable Product (MVP)” version of an open-source design made by the MIT Media Lab. The MVP was designed to be a plant growth chamber that integrated a computer to collect data and control the environment. We had three requirements:

- $300 budget to source parts from a hardware store or Amazon

- Can be completed by the average “DIY Hobbyist” or “Shop Teacher” (no 3D printers required)

- Software that allows you to view charts from hourly temperature/humidity sensor data and photos

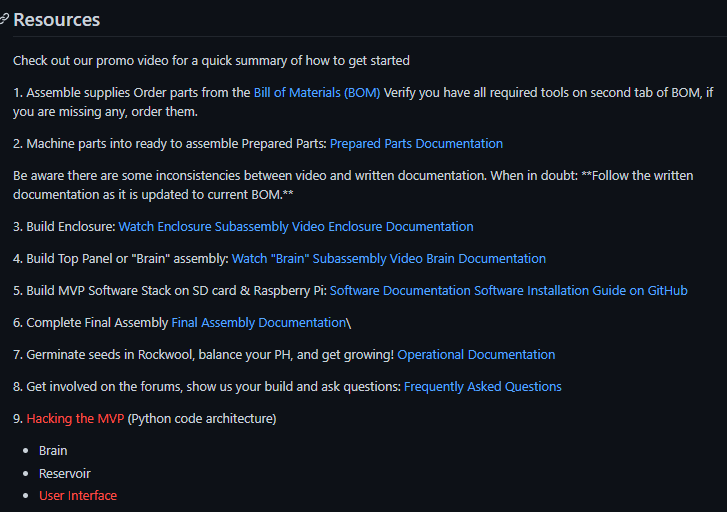

Start by watching this quick video to understand the design of the $300 Food Computer:

Learn how to build it yourself by following the steps outlined below:

GitHub documentation for $300 Food Computer: link to BOM, instructions, and software

After releasing the designs (on forums - just like these) the “$300 Food Computer” other community members began to post photos of their completed assemblies. Within a year, over 200 organizations in 10 different countries around the world had all built the growth chambers - and that’s just who told us. Most importantly to our future though, we were able to observe the ways that teachers and students actually used this technology - before even selling a single product!

MARSfarm was featured in a documentary called “Farming for the Future”, which was created by the largest open-source company in the world, Red Hat. This is a really well made 10-minute YouTube video that can be used to get students to think different about the skills a farmer of the future will need. I encourage you to watch it and maybe even use it in your classes - let me know if you agree!